About Company

Globally, HSCL is amongst the few completely integrated specialty carbon companies leveraging on its deep knowledge of one of the most versatile substances - Carbon. Over the years, with its core products and value-added by-products, the Company has established itself as one of the world's most extensive value chains in the Carbon segment. Our commitment to the Customers' success drives us to continuously develop innovative products with emphasis on R&D and focus on maximum utilization of resources. Our aspiration is to emerge as one of the leading specialty carbon chemicals conglomerate in the world on the back of an unmatched product portfolio, cutting- edge research and best-in-class technical capabilities.

We are headquartered in Kolkata and have seven manufacturing facilities in India and one state-of-the-art manufacturing unit in China. The Company has R&D facilities that are recognized by the Government of India, demonstrating a strong emphasis on technological innovation and research. We are continuously evolving our processes to improve our global footprints by improving energy efficiency levels and ensuring well-being of employees and nearby areas.

The commitment to our stakeholders - employees, shareholders, suppliers, customers and community, is of utmost importance to us and we aspire to achieve superior financial performance.

In 2016, Himadri has adopted a new logo. This is an aesthetically designed Butterfly. The butterfly signifies ushering in a new life and growth which accurately represent the values and the journey of our Group Much like the butterfly, Himadri is a vibrant, ever-growing and environment-friendly. The different wings of the butterfly symbolize the different facets and integrated nature of our Group. The multiple wings which emerge from the same focal point, signify multiple lines of our businesses, that though maybe different but work with close association to each other, all emerging from the same foundation – carbon.

Our logo has been designed to illustrate the wings of growth. The butterfly also symbolizes tenderness and care which truly reflect our Group's emphasis on sustainability of the eco-system it operates in and its approach towards its employees and other stakeholders. The colors yellow, orange, mauve and red evoke a sense of strength, energy, and growth. The logo and name colors combine the calm stability of blue and the fierce energy of red which represent the attitude of the conglomerate in planning its future goals. This change, will convey our brand message and strong identity more clearly, to all our customers and other stakeholders.

Research & Development

R&D: Our Prowess At Himadri, we believe the largest positive impact, as an innovation leader, is rooted in our experience and ability to deploy solutions that catalyse a more sustainable world. Our R&D team is actively engaged in developing environmentfriendly processes and products recognised by customers worldwide. Backed by highly qualified and dynamic professionals, we are developing solutions that are impactful and sustainable.

Our R&D team follows a path that best describes our passion and proven expertise in science and innovation. It is a testimony to how we create sustainable solutions for the complex challenges facing our world. Over the course of our long history, we have repeatedly proven that the most valuable and enduring business outcomes are the ones that are beneficial to society and keep the planet thriving.

Our products have great demand in the near future and possess tremendous potential to elevate our confidence going ahead. This same confidence helped us offset the current hiccups caused by the economic slowdown and Covid-19. Thus, reinforcing our belief to emerge as a strong player with a long-standing vision in Speciality Chemical space.

Products -

Advanced Carbon Materials -

Himadri manufactures high quality anode material for Li ion battery. Li ion batteries power Electric Vehicles, consumer devices like Smartphones, and Energy Storage devices. Himadri is the first and only Indian producer to commercially produce the Li-ion battery Anode material in India. We have the capability to produce both Natural & Synthetic variants of Graphite as well as Silicon composites.

Our in-house facility allows for all of the manufacturing processes involved starting from coal tar treatment till powder processing. Own facility also gives us the flexibility to manufacture customized material to suit the individual battery application for high energy density and high power battery application.

Carbon Black

Solution provider with capability to supply tailor made carbon black for individual applications

Lowest impurities in carcass and tread black

Backward integration into cleanest feedstock

Capability to produce ultra-high surface structure grades

Proven track record in quality and delivery over last decade

Coal Tar Pitch

Himadri is the largest Coal tar pitch manufacturer in India with over 70% market share in the space. The detailed quality processes ensure that it is the preferred material for use as a binder in the manufacture of Aluminum anode and graphite electrode. Himadri has developed and supplied a special grade of coal tar pitch to DRDO. Himadri has requisite approvals from the major Global and Indian Aluminum and graphite manufacturers. These are customized product, made specifically to suit customer requirements and desired quality specifications.

Himadri's CTP impart properties in the manufacturing of electrodes and provide superior quality of the product for ultimate benefits and economics at the user's end. At Himadri, coal tar pitch manufacturing process is very much advanced having series of fractional distillations with a latest technology and is the only plant in the country manufacturing pitch at low temperature applying vacuum, keeping in view complete control on environment and emitting zero pollutants in the atmosphere. To ensure highest quality and service to its customers, Himadri has raw material tie ups with all the major Indian and Global Steel manufacturers.

Napthalene Derivatives

Himadri utilizes state-of-the-art technology in multi stage refining units using which we produce chemically treated Naphthalene Oil which is distilled in Rectification/Fractionating Column followed by further purification in refiners. The raw material used is Naphthalene Oil extracted from high temperature crude coal tar, which is fractionally distilled in a series of distillation tower. Stringent monitoring by our highly skilled and experienced team makes it possible to achieve the target quality consistently.

SNF

This division manufactures Sulphonated Naphthalene Formaldehyde (SNF) condensate products at its Mahistikry in West Bengal and Vapi in Gujarat Plants under guidance of highly experienced technical persons using state of the art production system. Himadri Speciality Chemicals Ltd is the largest SNF manufacturer in India. These speciality products are used in Concrete, Agro, Rubber and Gypsum Board manufacturing. Products are also exported to Asia Pacific, Srilanka, Bangladesh, Middle East.

PCE

This division is manufacturing Polycarboxylate Ether (PCE) products at its Mahistikry in West Bengal and Vapi in Gujarat Plants under guidance of highly experienced technical persons using state of the art production system. Himadri Speciality Chemicals Ltd has the largest PCE manufacturing facility in India and an in-house R&D Centre with sophisticated instruments run by highly qualified and experienced persons. These speciality polymers are produced as per customised specifications and the range of products include from high water reduction, high water reduction/ slump retention , very high slump retention grades and are equivalent to imported products.

Corrosion Protection

The range of Anti- corrosion products is produced by using best quality High temperature carbonisation Coal Tar that has the optimum resistivity to both Acid and alkali attack. In all climatic condition and severe salinity of sea water, the anti - corrosion products developed by Himadri is ideally suitable with very long protective duration

Speciality Oil

Himadri has developed special types of oils to cater to different industries. These are the by-products of our state-of-the-art multi-stage coal tar distillation process. The distillation process is continuous and not the conventional batch process. The process is carried out through a series of fractional distillation columns. Specific qualities/grades of oil are cut off from the distillation process. Ultimately, the customized products are formulated by blending different cut oils in specific ratios to suit downstream requirement of customers' product processing.

Power

Himadri generates clean and green power, which is marketed to the state electricity grid and consumed in-house. Himadri uses low caloric value waste gas coming out from Carbon Black Process which is utilized in the Boilers. Boilers are especially designed to generate High Pressure & High Temperature steam. This High Pressure & High temperature steam in turn drives the Turbo- Generators to generate Power. We are using as much process energy possible which would otherwise have gone waste to fulfill our commitment of energy conservation & environment protection.

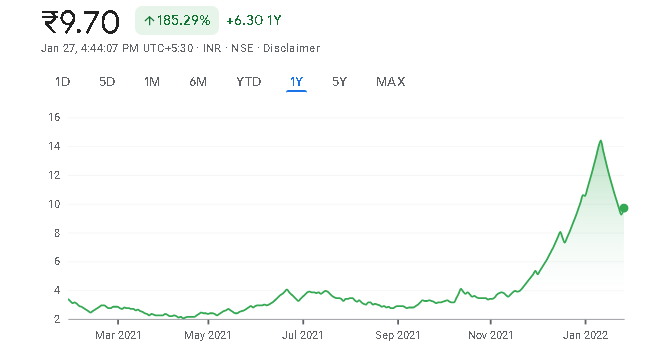

Share Performance - 1 year

The image below shows the yearly returns to the investors.

The scrip is likely out perform and reward investors well in next 18-24 months. Investors should wait for price dips add to their portfolio of this specialty chemical company for superlative returns.