About Bhandari

We inherit a long textile manufacturing background and specialize in circular knitted manufacturing. We are a fully integrated textile company in INDIA, focused on fashion supply for leading retailers and brands worldwide. We provide customers with a comprehensive textile solution - from design and development to knitting, dyeing, finishing and garmenting.

Our broad range of offerings, technical expertise, international reach and state-of-the-art in-house manufacturing facility, allow customers to get the design solutions they need. However, we are not your typical large company. Our individual customers get the attention to details and our unparalleled support at every step. We are a committed team of experienced designers, merchandisers, quality controllers, and production managers with a high level of fashion sensibility to cover and support all development and manufacturing levels.

Design & Development

All products start with designing.

We understand and recognize the importance of product design and development. Through effective fabric engineering, we turn complex concepts into simple production friendly patterns that meet fashion and quality requirement.

With extensive knowledge of design and sampling capabilities, we act as a design partner for our customers. Team, together with our customers, develops prototypes and samples with added value based on quality, design and pricing.

Knitting

Company develops and manufactures a host of knit fabrics for a variety of fashion markets. Our current fabric processing facilities contain a wide range of options in terms of blends of fabrics, patterns, treatments, finishes and widths. Company works alongside you to design and manufacture an exact material to meet your performance requirement.

Company guarantees a fast response to your fabric requirements and offer short lead times, supported by our in-house planning and order processing team.

Company has a manufacturing capacity of 500 tons per month in Open width and Tubular width. We specialize in polyester, viscose and lycra blends. In case of SUSTAINABLE FABRICS we work with organic cotton, tencel (eucalyptus), modal and recycled polyester.

Jersey Knit - Single jersey (18 - 36 gauge), Double Jersey (12 - 28 gauge), Jacquard (18 - 28 gauge), Knit wear (7 - 12 gauge)

Viscose Elastane, Ponti (Ponte), Rib, Milano, Stripes

Viscose, Poly Viscose, Cotton, Spun Polyester, Polycotton, Nylon, Lycra, Microfibre & more

Manufactured to customer specifications - in widths from 1m to 1.75m

Fashion Fabrics › Printed fabrics › Fleece › Loopback › Single Jersey › Double Jersey › Jacquard › Ponti (Ponte) › Ponti roma › Rib Knit › Milano › Knit wear › Linings › Stripes

Dyeing

We can offer a wide range of dyeing solutions for various fabrics. All our Soft flow fabric dyeing machines are from Dong-A Korea. They are the lowest liquor ratio machines available in the industry. Fully automatic, centrally controlled and programmed from the Lab.

High quality Dyes (reactive, directs, disperse) are sourced from reputable suppliers - selected to achieve the highest standards of color fastness to meet customer requirements. All are dyes and chemicals are OEKO-TEX certified which provides us the confidence that our fabrics uphold legal and environmental standards and do not contain harmful substances.

Company has state of the art RO Plant to treat water and reuse the treated water for dyeing. Not even a single drop of water is discharged outside the plant premises.Our commitment towards the environment encourages us towards sustainable methods of production.

Finishing

There are endless combinations of constructions and special finishes that we can adopt in our facility. This includes

Flame retardancy (Durable/Non Durable)

Water repellency (including PFC free chemistry)

Oil / stain repellency

Anti-fray

Shrinkage control

Crease resist/Easy care

Infra-red reflectant

Anti-bacterical / Anti-microb.

Peach skin finish (Emerize)

Calendar smooth finish

Slitting and Seal

With the below machinery, we offer a wide variety of processes,both chemical and mechanical, to add specific performance and aesthetic characteristics to fabric.

Fully equipped stenters from EHWA KOREA (6 chamber double padder with special Lycra heat setting and computerized control system)

Weft Straightener: Bianco Italy

Slitting Line for open width fabrics: Bianco Italy with Bio wash tanks

Open Width compactor: Poong kwang Korea

Tubular Compactor: Tubetex USA

Raising and Shearing Machine Laffer

Garments

Developing the perfect fabric and then cutting and processing it with perfect accessories is vital to create the ultimate finished garment for our customer.

We manufacture all kinds of knitted garments for Men, Women and Kids. At Bhandari we have a vast range of fabrics and we are skilled in working with a wide range of yarns and fabrics, colours, prints, packaging, labelling and all things associated with garment.We constantly update our collection and present to our clients the latest trends so as to create the best possible style.

Our team understands the fast moving and time constrained fashion world. So we have in place a working system that enables us to offer our customers short lead times. Our premises are ultra-modern and with design, production, inspection and testing all under one roof, we oversee the complete production process, from the first sample to final delivery. We have a production capacity of 400,000 pieces per month.

Printing and embroidery

We work with transfer prints, screen print, digital prints and sublimation prints to develop multicolored vibrant prints out of simple graphics.Furthermore, we enhance the garment with embroideries and embellishments of textiles, metal etc.

Inspection and testing

Establishing the precise level of testing and certification for each application is an early priority for our in-house quality assurance team. Independent testing can be arranged to certify product performance.

Quality Assurance

We have a fully equipped in-house laboratory to dye and test fabrics to meet customer requirements and industry standards.

Dye Laboratory

Lab dyeing

Color matching to pantone standards

Develop recipe, using latest data color software.

Lab application of various finishes

Testing Laboratory

Flame retardancy

Tear and Tensile

Abrasion

Perspiration

Wet and dye rub

Oil and water repellent

Wash and colour fastness

IRR

Shrinkage

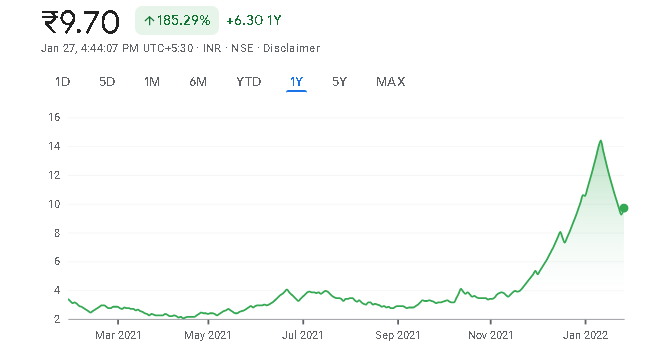

Stock Performance - 12 Months

The scrip has given 185% returns in the last 1 year had a year high of Rs.14.70 and year low of Rs.2 currently trading at Rs.9.70

Investors should buy this penny stock as the company is likely to out perform in next 2-3 years timeframe.

No comments:

Post a Comment