About Company

Today, with an installed capacity of over 35000 MT/year being increased to about 45000 MT/year by 2019, we are the largest producers of Winding Wires in South Asia. Our state-of-the-art facilities at Silvassa manufacture a wide range of products including Enamelled Round and Rectangular Copper Winding Wires, Continuously Transposed Conductors (CTC) and Paper/Mica/Nomex® Insulated Copper Conductors (PICC), which are used across the globe by the electrical/electronics industry.

Over the years, our wires have been synonymous with the very best in quality, reliability and integrity.

This, with our long history and expertise in the industry has enabled us to develop long term associations with the top manufacturers across applications, such as motors, transformers, generators, compressors, automobiles, hand tools, fans, relays, ballasts etc.

Products

Enamelled Round Winding Wires

PWIL today manufactures a wide range of Enamelled Round Winding Wires for use in electrical machines such as motors, generators, transformers, house hold appliances, auto-electricals, electrical hand tools, refrigeration (hermetic) motors, fans, switchgears, coils and relays, ballasts and etc.

Enamelled Rectangular Winding Wires

Enamelled Rectangular Copper Wires are used in low and medium voltage electrical machines such as motors, generators and transformers. The cross section of these wires ranges from 3.0 to 75.0 square milli metre with an insulation Class ranging from 105 to 220 degrees Celsius.

Rectangular Enamelled Copper Wires

Poly Vinyl Acetal, Class 105, 130

Polyester, Class 130 and 155

Polyesterimide 180

Dual Coated Polyester (imide) + Polyamide imide, Class 200

Polyamide imide, Class 200

Polyesterimide Bondable, Class 155 and 180

And Other insulation Coatings according to customer specifications

Paper Insulated Copper Conductor

Rectangular Taped Conductors of various types are used as winding wires in a variety of high voltage applications such as, Oil filled Power and Distribution Transformers, Dry Type Transformers, High Tension Motors/Generators, and Traction Equipments.

Our Product Range

Paper Insulated Rectangular Copper Conductors as per IEC 60317-27 as well as Customer Specification

Nomex™ Insulated Rectangular Copper Conductors

Mica Tape Insulated Rectangular Copper Conductors

[All the above can be offered with controlled Proof Stress]

Type of Insulating materials

Applications

Oil filled Power and Distribution Transformers

Dry Type Transformers

High Tension Motors/Generators

Traction Equipments

Continuously Transposed Conductor

Continuously Transposed Conductors are used in Large Power Transformers, generally more than 50 MVA, Furnace Transformers, and Traction Locomotive Transformers. The current production range of CTC is between 5 to 72 strands with a variety of different insulating materials.

WHAT IS CTC?

CTC consists of a group of enamelled rectangular wires, which are connected up parallel to the ends. In the group each strand (enamelled rectangular wire) successively and repetitively takes up every possible position in the whole cross section. The bunch is wrapped with oil compatible pure cellulose paper.

WHAT IS TRANSPOSING?

The enamelled wire conductors within CTC are arranged in two parallel stacks. One stack having one more conductor that the other. The conductors are continuously transposed by machine action moving them from position to position in discrete steps:

Step1: Conductor 1 is moved from the top of the left hand stack to the top of right hand stack.

Step2: The right hand stack is moved down one conductor thickness in relation to the left hand stack.

Step3: Conductor 3 is moved from bottom of right hand stack to the bottom of left hand stack.

Step4: The left hand stack is moved up one conductor thickness in relation to the right hand stack.

At the end of four transposing step, as shown in the figure, the CTC conductors have returned to the original geometry, but each conductor advanced one position clock-wise.

Source - precisionwires.com

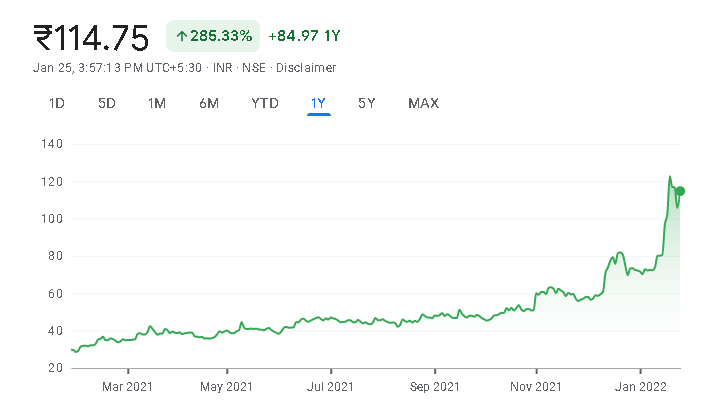

Stock Performance - 1 year

Company had a spectacular run since last 1 year has given 3x returns to the investors. Looking at the growing demand for the products investors should continue to hold. New investors should look at buying on dips and add to their portfolio.